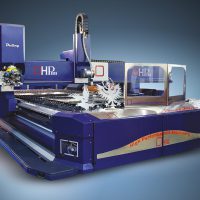

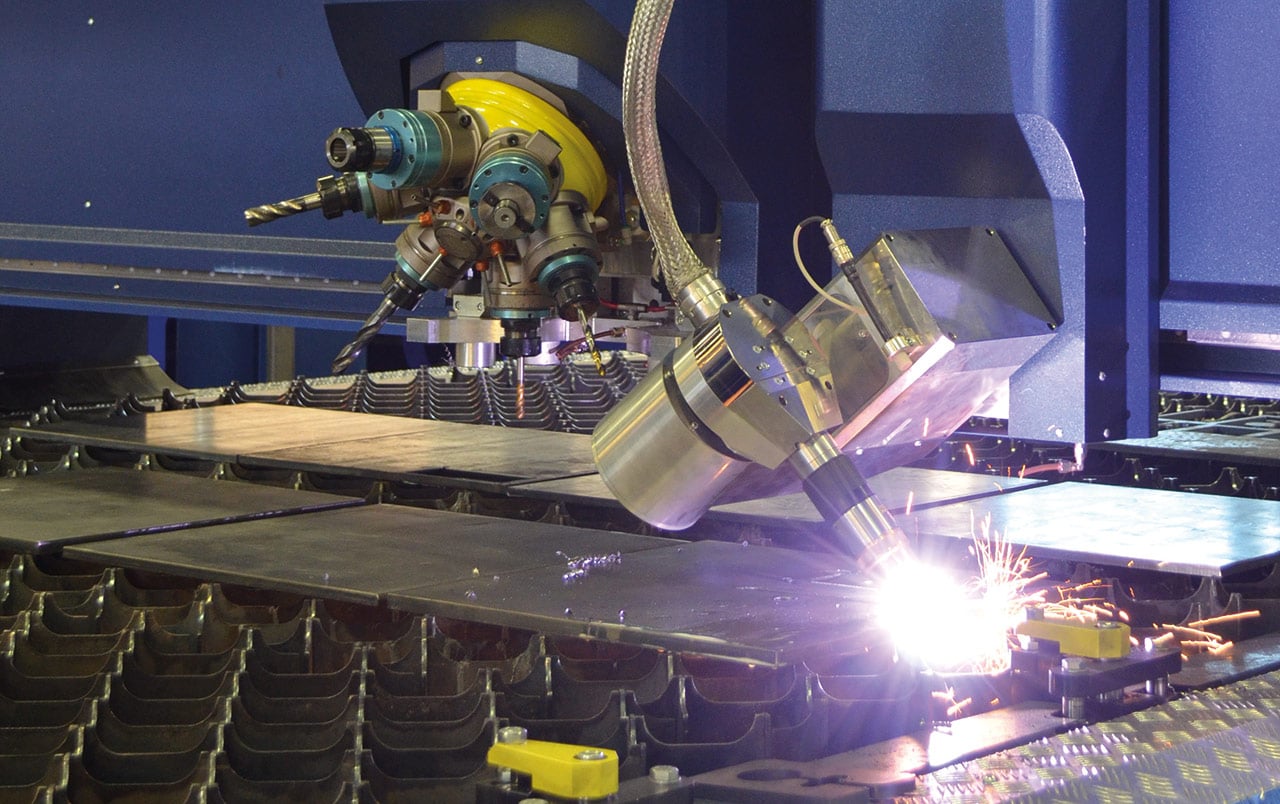

Plasma cutting machine Steel Max

Steel Max is the biggest and strongest plasma cutting machinery of our range, which is possible to integrate with many different accessories.

Features Steel Max

Even the Steel Max model is built with a lower modular steel frame and an electro-welded aluminum crossbeam , all specifically sized to support drilling tools and combined accessories.

The use of the aluminum crossbeam ensures lightness, strength and elasticity, and allows the machinery to be strong, precise and fast.

Like all HPm machinery, prismatic guides and rectified racks are housed in the side beam; in the upper part, where the crossbeam slides, this center of gravity allows a perfect balancing, which is useful for the accelerations and for cutting accuracy. The CNC and the electronic part ensure the machinery to be efficient, reliable and easy to be managed.

The bench for the laying of the sheet is separated from the rails and is divided in suction segments with shutters automatically controlled by the CNC. The upper part of the table consists of frames or grid sectors of several models, chosen according to the type of accessories that make up the machinery.

Steel Max, like all the other HPm models, besides quality, does not neglect the stylish details, that make it stand out within the workshops where it is used.

Steel Max uses brushless motors with absolute encoders, extremely high precision gearboxes, recirculating ball screws, ground pinions and racks, skates and prismatic guides.

Steel Max is produced in cutting sizes of 1.5 – 2 – 2.5 – 3 – 3.5 meters in width, while even 40 meters in length.

We can produce personalized machinery, according to the needs of the customer;

The basic configuration consists of the single straight plasma torch, provided with a 360° anti-collision system to protect it from unexpected obstacles during the movement of the axes and electronic height control;

Two or more complementary technologies can be combined in a single machinery, by using the same structure, CNC and Software;

On this machinery any type of plasma generator can be installed.

Accessories Steel Max

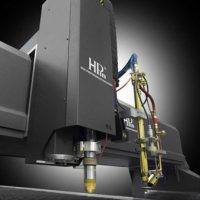

“Bevel” Head for 5-axis beveling

Bevel head with unlimited rotation and possibility of inclination up to +/- 47°, provided with automatic rotation of the angle of inclination, allows to make bevel cuts, etc.

6 Spindle Drilling head or Single Spindle Drilling Head

The spindle drilling Unit as well as the Iso 40 single spindle, have a 6-position tool changer with automatic selection and quick change, which allow performing various types of machining such as drilling, threading and flaring on various sheet thicknesses.

The robust crossbeam is designed to support the pressure of tools in the process of drilling and threading, without bending; The automatic blank holder ensure the stability of the sheet during processing.

Thanks to the integrated cooling and lubrication systems, a perfect execution of the counter is granted and tools preserve a longer life cycle .

In the numerical control are integrated all the advancing and cutting parameters which are divided according to thickness and type of material.

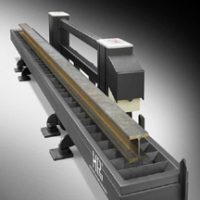

Lift unit for profiles and tubular

The robust structure of Steel Max model allows to support a lateral extension of the crossbeam without bending. Thanks to the counter with adjustable height, you can work on a vacuum table several types of profiles and pipes with square and rectangular section.

Pipes and Profiles Cutting

Pipes and profiles cutting accessories can be produced with positioning and locking both manual and automatic.

The maximum useful length of the pipe or profile is 14 mt.

Round tube cutting

A rotary tool with spindle is used for the processing of round tubes.

The models produced differ according to the spindle capacity and the structure:

- – Diameter of the pipe to be cut ranging from 50 to 600 mm

- – Diameter of the pipe to be cut ranging from 50 to 900 mm

- – Diameter of the pipe to be cut ranging from 50 to 1200 mm

Cutting of profiles

In addition to the round tube, it is also possible to cut square, rectangular and beam tubes with standard sizes from 50 to 550 mm. For higher sizes or conical polygonal section tubes, special customized plants are produced.

Oxy-fuel torch

With the addition of this accessory, it is possible to cut the steel with a thickness greater than that allowed by the plasma technology, preserving the qualities of precision and speed of axis movement.